This project re-imagines the traditional gridshell structure, by imbuing it with localised moments of tension through a system of eyelets, affording the overall form greater structural integrity and a more nuanced formal articulation.

Through rigorous physical testing, digital prototyping, and simulation, this bending-active gridshell structure is an exploration in the lineage of gridshell form-finding and the mediation between digital fabrication techniques and the specificity of physical craft with regards to material properties.

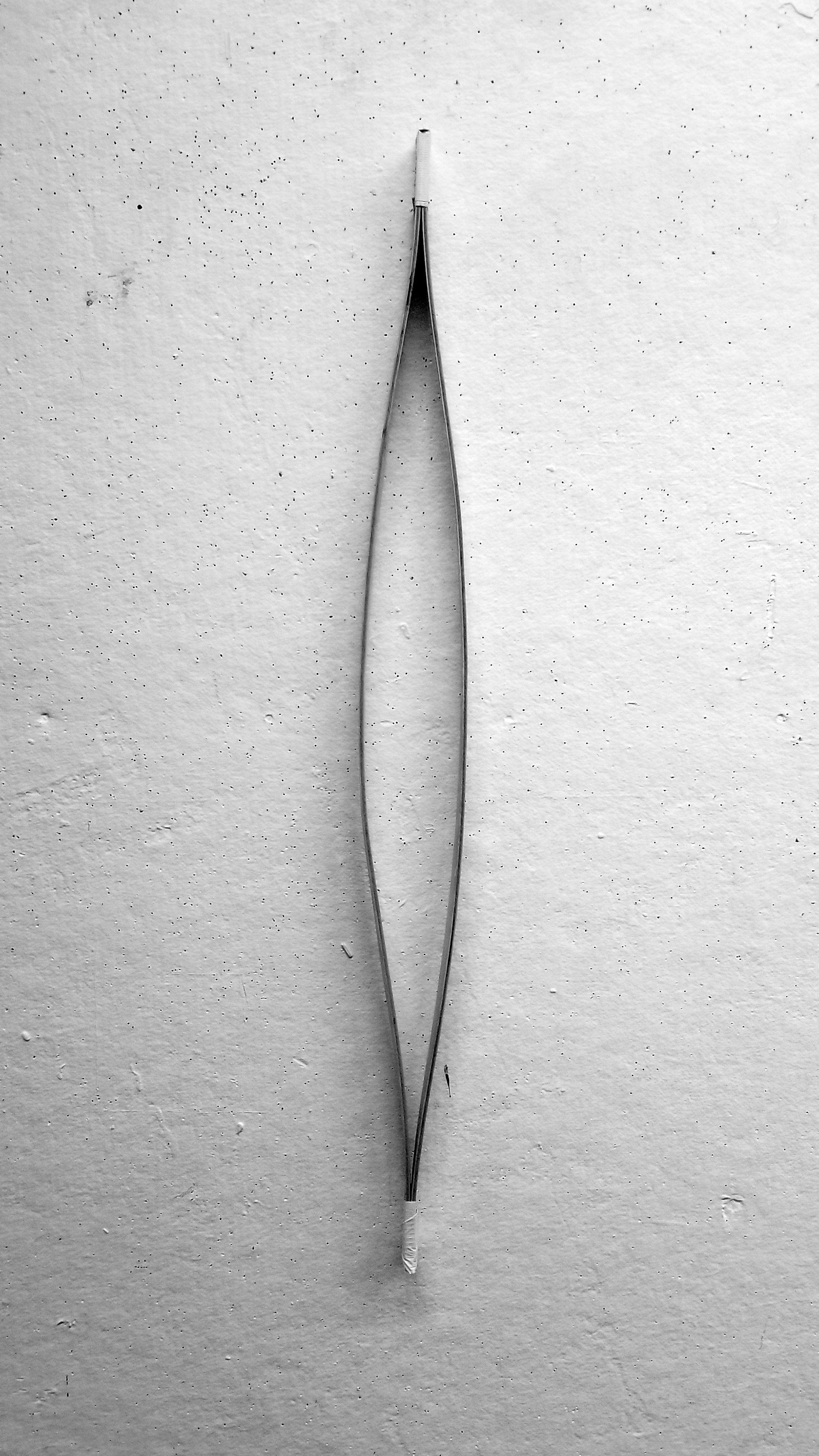

The quilted form is actuated and locked in place by a system of steel cables which also serve as a scaffolding for supplemental shading/ambient elements.

TESTING

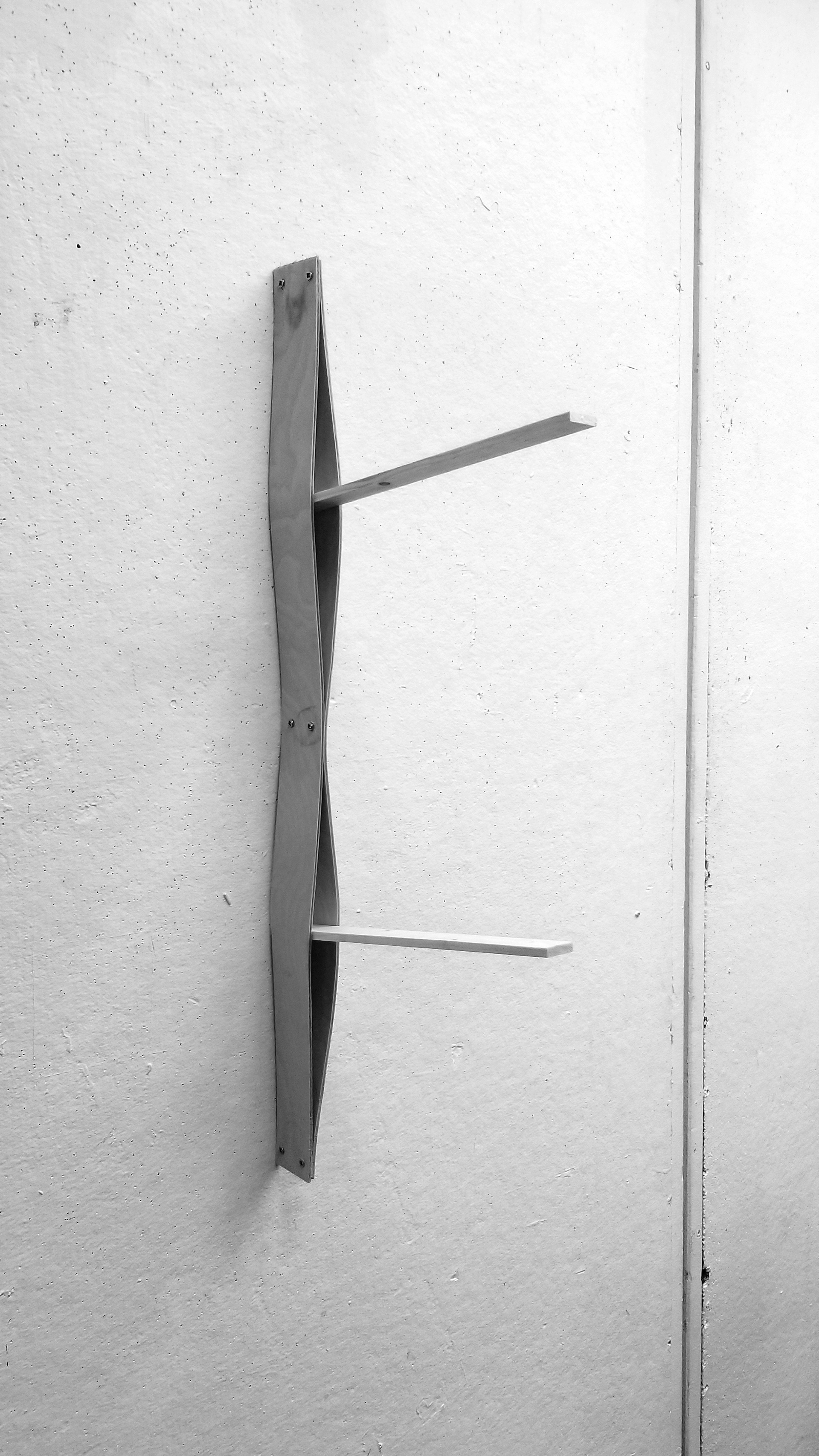

Bend tests for different wood types - Ultimately decided on Birch Plywood based on strength, flexibility and availability

FABRICATION

Mill and soak

Assemble lathes

Assemble grid

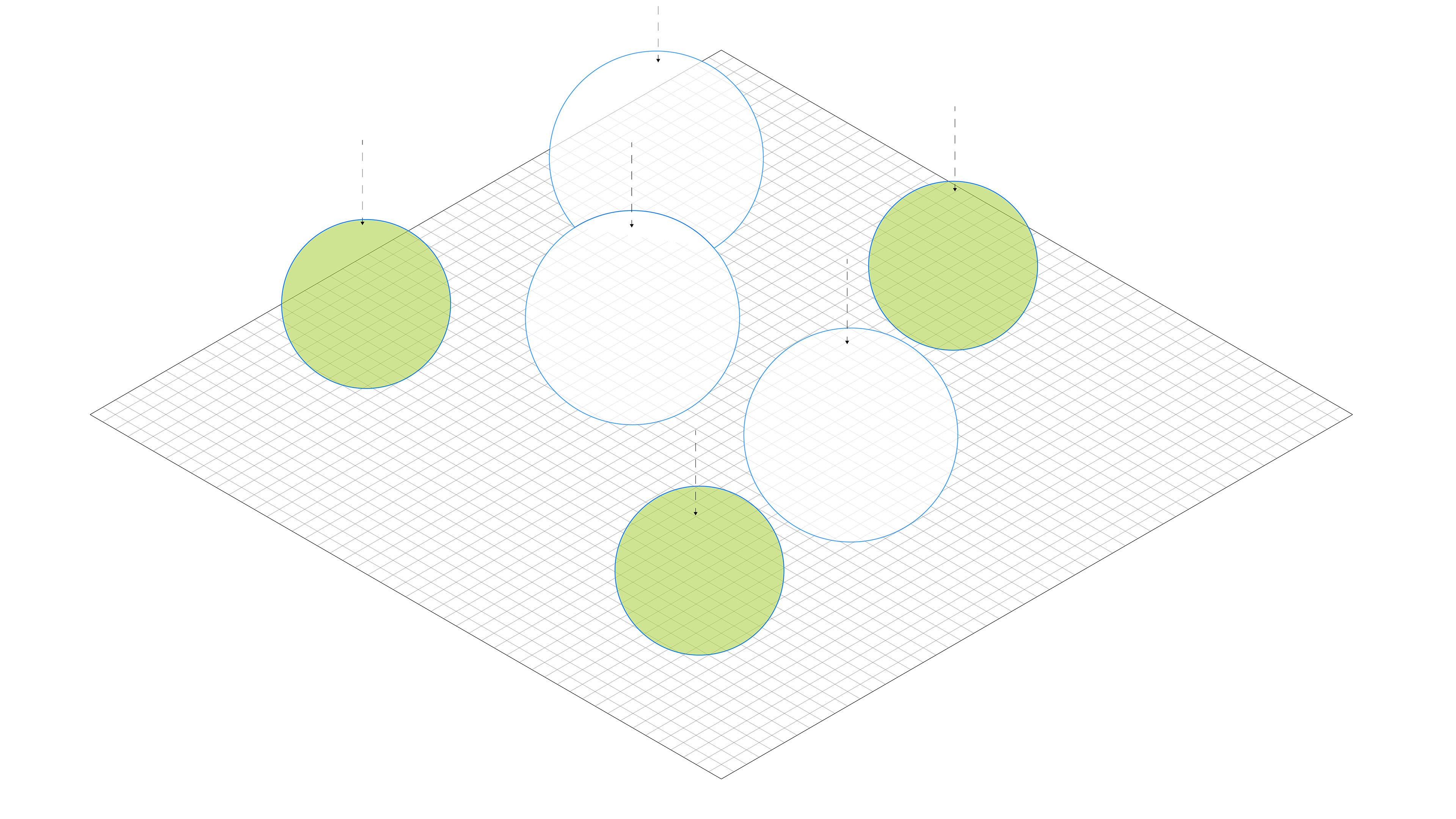

FORM FINDING + DEPLOYMENT

Undulating fabric with the lowest troughs acting as feet to anchor the form to the ground